Suzhou Kiande Electric Co., Ltd. is a professional enterprise integrating R&D, production and sales. It has more than ten years of rich experience in the electrical field. The intelligent storage system developed and produced has been obtained in the domestic and foreign markets. Received a very high evaluation and became one of the world’s leading manufacturers.

Suzhou Kiande Electric Co., Ltd.’s smart warehousing combines the most advanced production technology and R&D experience at home and abroad, and uses advanced software technology, Internet technology, automatic sorting technology, light guide technology, radio frequency identification, voice control technology and other advanced technologies. Scientific and technological means, fully automated to realize the entry and exit, storage, sorting, packaging, distribution and information management of items.

Intelligent Warehousing Recommend Products

Intelligent Warehousing Detail Introduction

Now that the logistics industry has entered a period of rapid development, the application of intelligent warehousing can effectively improve the speed and accuracy of data input in all aspects of cargo warehouse management. It is essential to the development of logistics and is also the best embodiment of modern technology. Therefore, an intelligent warehousing system has very high market demand.

If you want to know more about this industry or want to improve your warehouse operation level, welcome to contact us, we can customize the smart warehouse system that suits you best, and can provide you with the most comprehensive quotation, look forward to working with you!

Smart warehousing

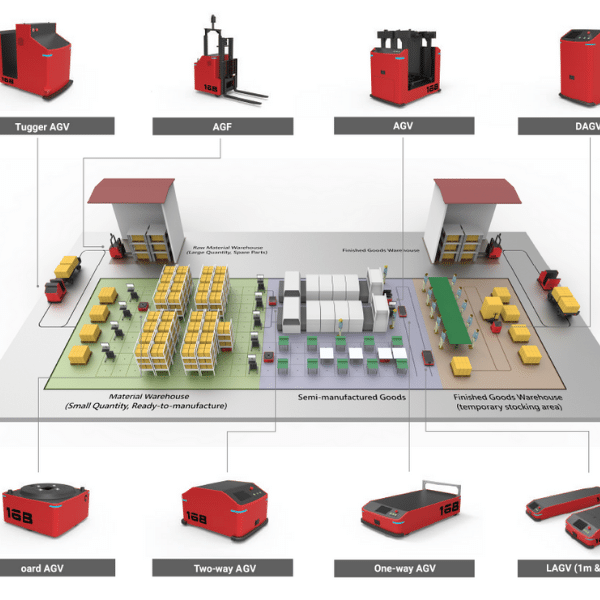

The basic components of intelligent warehousing: identification system, handling system, storage system, sorting system, and management system.

Storage management: It can realize the complete storage process such as receiving, quality inspection, and putting on the shelves. It can realize the first quality inspection and then the harvesting and multi-scenario harvesting. The target storage location can be automatically obtained according to the goods putting strategy, and then manually or machined The goods are delivered to the designated location and can be put into storage after scanning.

Outbound management: It can automatically complete the processes of picking, packing, and boxing. After sending out the warehouse task, the equipment will go to the designated warehouse according to the designated route and then be transported to the outbound area after the goods are obtained. The database will be updated after scanning and review. Delivery is completed.

Inventory management: After the device creates an inventory task, the library manager uses the mobile terminal to view the inventory task and perform an inventory. After that, the data is compared with the information in the database, and the difference is displayed on the mobile terminal. After the inventory is completed, the information is checked with the information in the background database to generate an inventory table.

Visualized location management: Visualize warehouse location information, and display the inventory status of each location in a plan view, so that the staff can better understand the information in the warehouse.

Early warning management Provides various early warnings, including early warning of the near expiration date, overtime warning of documents, early warning of emergency task jam, early warning of the upper and lower limit of inventory, and early warning of low turnover.

Sorting management: The pallet palletizing robot can automatically place goods of different dimensions on the pallets neatly.

More explanation:

The intelligent warehouse of Suzhou Kiande Electric Co., Ltd. has introduced the most advanced production technology at home and abroad and has the most advanced technological level. It can fully automate the warehouse's storage, delivery, sorting, management, and transportation processes.

Our warehousing system can realize intelligent control, fully meet everyone's high standard requirements for warehouses, help companies realize efficient storage methods, allow staff to better grasp relevant information about the warehouse, and improve the efficiency of warehouse management. .

The rapid economic development has made all walks of life have entered a stage of rapid development, and the requirements for warehouses are getting higher and higher. However, the traditional warehouse management model has many shortcomings, such as difficulty in tracking goods, high labor costs, and management. With backward methods and serious loss of goods, this kind of warehouse management model can no longer meet the needs of modern production. Intelligent warehousing is adapted to the development of the times. It uses the most advanced technology and is a new warehousing method urgently needed by major enterprises.

Our intelligent storage system can effectively save floor space and help enterprises save more space. In the same area, the storage capacity of intelligent warehouses is even ten times that of ordinary warehouses, which greatly improves the utilization rate of land. Help companies effectively reduce site costs.

Intelligent warehousing has a highly automated management method, and the operation time has been greatly shortened due to the characteristics of rapidness and accuracy. Not only that, the accuracy of the operation is greatly improved, which is of great significance for helping enterprises to form a good reputation. Fast and accurate warehouse management methods will provide enterprises with a very complete guarantee. In addition, the intelligent warehousing system can store goods of various shapes and sizes. The number of goods stored is large and diverse. However, the management system is not messy but can achieve accurate cargo tracking and fully automated management. In this way, the management level of the warehouse will be greatly improved.

Suzhou Kiande Electric Co., Ltd.’s intelligent warehousing has reached the world’s leading level and has been very well applied in many countries and regions. It has provided great help to local enterprises and contributed to the local economic development. Outstanding contribution.

Although our smart storage performance is very superior, you don’t have to worry about the price at all. Our project effectively controls the production cost, so we can give our customers the most favorable price, and we will also provide a very complete service to solve you With all the doubts, your business can get better development with the help of our smart warehousing.

We invest a lot of money in research and development every year, so our intelligent warehouse has won a variety of innovative awards, which has attracted many companies to invest. This indicates that we have a very strong ability to innovate, and we never stop In the footsteps of innovation, we are always working hard to promote the development of science and technology.

Because major companies have a very high demand for smart warehousing, you can contact us if you need it. We also sincerely hope that more domestic and foreign customers can come to our company for on-site inspections. We always speak with quality. We firmly believe that we can provide you with the most cost-effective intelligent warehouse!

Smart warehousing: a complete buying guide:

Warehousing is the basic guarantee for the development of an enterprise. The warehousing capacity will represent the market scale of the enterprise. Smart warehousing can increase the storage capacity more than ten times on the same area.

For some common questions about warehousing and smart warehousing, the following will give you detailed answers:

1. What is the importance of the warehouse?

The warehouse is the most basic existence in the operation of an enterprise. Doing a good job in warehouse management is the basis for the smooth operation of the enterprise. If there is a problem in the management of the warehouse, it will cause problems in the supply of the enterprise and fail to respond to the needs of customers in a timely manner. It directly affects the overall development of the enterprise and has a very unfavorable impact on the enterprise.

2. What is smart warehousing?

Intelligent warehousing is a new warehousing management concept that uses a variety of advanced technologies, such as RFID, AGV, robotic palletizing, three-dimensional warehouses, warehouse management systems, and warehouse control systems to automatically control the warehousing of goods, Outgoing, transportation, sorting, packaging, etc., thereby effectively reducing storage costs, improving operational efficiency, and improving storage management capabilities.

3. Benefits of Intelligent Warehousing

1. The use of advanced Internet of Things sensing technology, automatic identification technology of two-dimensional code of goods, electronic display technology, etc., make the management of goods easier, greatly reduce the labor required, and effectively reduces labor costs.

2. In the case of the same area, the storage capacity of smart warehousing is greatly improved, which is more than ten times that of traditional storage methods, which expands the storage capacity of the enterprise and can help the enterprise to further expand the market scale.

3. With a fully automated operation method, the accuracy rate is higher, the speed is faster, the time is greatly shortened, and the storage level is effectively improved.

4. It can store many types of goods, no matter what shape or volume, only need to use barcode technology to quickly track and manage the goods.

5. The intelligent warehouse management is simple, the loss is low, and the customer response speed is fast, which can effectively improve the operation efficiency.

4. Limitation of Intelligent Warehousing

Because intelligent warehouses have realized fully automated operations, used a variety of advanced technologies, and extensively relied on mechanized equipment for operation, this is the biggest advantage of intelligent warehouses, as well as the most obvious drawbacks.

1. It is composed of a variety of equipment, and the structure is much more complicated than that of ordinary warehouses, and installation and disassembly are more difficult.

2. The requirements for warehouse management personnel are relatively high. Ordinary workers in traditional warehouses can be competent, while the staff in smart warehouses need to undergo rigorous training and master advanced technology.

3. If a certain device in the smart storage is damaged, it is likely to cause the entire operation to malfunction.

5. How to Verify Quality of Intelligent Warehousing

Verification of the quality of smart warehousing needs to be carried out from multiple aspects, such as the quality of the equipment, functional layout, safety and stability, operation efficiency, operation quality and after-sales service, etc. If you want to use an intelligent warehouse, you should start from the above To verify the quality, only if all aspects meet your requirements can it prove that this equipment has a relatively high quality standard.

6. How much Intelligent Warehousing Cost

The price of smart storage is affected by many factors, including the degree of automation, storage capacity, equipment quality, etc. Therefore, the price will also vary greatly, ranging from several thousand dollars to tens of thousands of dollars. You need to choose when choosing Choose according to your actual situation.

Suzhou Kiande Electric Co., Ltd. has very rich experience in this industry. The intelligent warehouse developed and produced has a very high-quality standard, and in many years of research and development, it has effectively controlled the production cost and can provide The most favorable price for our customers.

When you buy, you must not just look at the price. The low-priced ones will definitely be of poor quality. The later repair costs will be very high, but the high-priced ones are not necessarily suitable for you. You should choose the most cost-effective one according to your production needs.

Although we can't promise you that our smart warehouse has the lowest price in the industry, you can believe that our smart warehouse must be the most cost-effective at the same price. You will buy the best performance at the lowest price.

7. How to Troubleshoot Intelligent Warehousing

1. Motor blocked: Check whether the electromagnetic brake of the motor is in the open state, and judge whether the stacker crane is overloaded due to mechanical reasons.

2. The motor protector trips: check the resistance of the motor, and measure whether the motor circuit is intact.

3. Inverter alarm: Find the cause according to the alarm code and give the corresponding solution.

4. Stacker alarm: Check whether the alarm is caused by the irregular shape of the goods.

5. Cannot start normally: check the motor and switch, and check whether the circuit is damaged.

8. How Intelligent Warehousing Works

Intelligent warehousing adopts advanced automatic control technology, intelligent robot palletizing technology, intelligent information management technology, mobile computing technology, data mining technology and other technologies to realize the management of goods in, storage, transportation, sorting, and out of the warehouse. , With a fully automated operation method, it can effectively improve the management level of warehousing and improve the work efficiency of the enterprise.

The main access of the storage system includes the following three aspects: the vertical lifting system will transport the goods to the storage location designated by the system, the pallet in and out mechanism will change the storage position of the pallet, and the door opening and closing mechanism will complete the opening or closing of the door when the goods are obtained. The three electrodes of the system are controlled by the same frequency converter and regulated by the control system.

9. Support Equipment to buy with Intelligent Warehousing

Intelligent warehousing realizes a fully automated operation method. If you want to achieve a higher level of efficiency, you need to use some supporting equipment, such as auxiliary warehouses, support institutions, storage machines, outgoing machines, inquiry machines, etc., so that you can more The coordinated operation makes the operation more efficient and accurate.

10. Intelligent Warehousing Maintenance Process

Intelligent warehouses can realize high-efficiency management of large-area warehouses. For some large enterprises, intelligent warehousing can help them greatly improve production efficiency, respond to customer needs faster, and gain a broader market. In order to effectively extend the use time of intelligent warehouses and reduce subsequent maintenance costs, maintenance should be carried out in a timely manner during daily use.

Cleaning: Clean up the garbage in the warehouse to prevent malfunctions during the operation of the equipment. The vulnerable parts of the equipment should also be cleaned in time. Sometimes many major problems are often caused by untimely cleaning. Timely cleaning can Effectively extend the use time of the intelligent warehouse.

Inspection and maintenance: Any equipment will have a certain amount of wear after a long time of use. Therefore, it is necessary to set a time for inspection and maintenance and replace the worn parts in a timely manner. Do not drag some small problems into major problems, which will lead to the final cost of more maintenance. funds. In many cases, although the equipment is still running steadily, internal wear has already appeared. If things go on like this, huge failures will occur.

11. Intelligent Warehousing Validation Documents

Suzhou Kiande Electric Co., Ltd.'s smart storage has obtained ISO9001 certification, CCC certification, MIC certification, FDA certification, SGS certification, and many other international certifications, as well as some innovative awards. If you need it, you can leave us a message. We will send you the relevant certificates.

12. Parts of Intelligent Warehousing

Intelligent warehousing is a link in the logistics process, which can increase the speed of goods circulation, improve the accuracy of warehousing management and work efficiency, and bring great convenience to enterprises. The intelligent warehouse is composed of a three-dimensional warehouse, conveying equipment, palletizing equipment, sorting equipment, lifting equipment, and management software system.

1. Three-dimensional warehouse: It is composed of high-level racks, material handling equipment, control, and management equipment, and civil engineering public equipment, among which high-level racks can be several, a dozen, or even dozens of stories high.

2. Conveying equipment: There is a variety of conveying equipment to choose from, including chain and roller conveying equipment, plate chain conveying equipment, hanging conveying equipment, and stacker equipment.

3. Palletizing equipment: including joint robots and integration, truss robots and integration, spider robots and integration, etc.

4. Sorting equipment: including cross-belt sorting equipment, universal ball sorting equipment, slider sorting equipment, inclined guide wheel sorting equipment, etc.

5. Lifting equipment: including spiral lifting equipment, continuous lifting equipment, reciprocating lifting equipment, etc.

6. Management software system: including WCS intelligent management and control platform, WCS monitoring system software, WMS warehouse management software, interface application software, etc.

13. Industries using Intelligent Warehousing

Intelligent warehousing is currently widely used in logistics, automobiles, electronics, e-commerce, medicine, food processing, trade, and other fields. It can be said that it is closely related to our daily life. The development of intelligent warehouses will greatly promote the rapid development of society. Provide us with a simpler and more efficient lifestyle.

14. Types of Intelligent Warehousing in the Market

Smart warehousing mainly includes low-level smart warehousing, high-level smart warehousing, penetrating smart warehousing, and automated cabinet smart warehousing. The performance and price of each type will be different. For different companies, they need to be based on their actual conditions. To choose the most suitable storage method.

15. Future of Intelligent Warehousing

Intelligent warehousing systems have made very good achievements and have provided a very strong driving force for the development of modern society. In the future, the market demand for intelligent warehousing will continue to increase, ushering in a more prosperous period of development. At the same time, the intelligent warehousing system will also develop in the direction of networking and intelligence and will be closely integrated with all links in the industry to achieve complete coordination, instead of being in a state of separation from other links.

16. Why choose Suzhou Kiande Electric Co., Ltd.'s smart warehousing?

Suzhou Kiande Electric Co., Ltd. is a leading manufacturer in the electrical field with very advanced R&D and production experience. The intelligent storage system produced has been exported to Singapore, Japan, Russia, the United States, India, and other countries and regions, Leading the development of the local warehousing industry.

To this day, although we have achieved good results, we have never been satisfied with this, and have always been committed to R&D and innovation, and can make great progress every year. Our intelligent warehousing system is of reliable quality, stable operation, high degree of automation, and has a very high operating efficiency and accuracy rate, which can bring a lot of convenience to the development of the enterprise.

The most important thing is that we can provide very low prices on the basis of ensuring quality so that more companies can benefit from this. We can also provide a very complete service, if you need it, welcome to contact us, we will customize the intelligent warehouse for you, and look forward to cooperating with you!