Suzhou Kiande Electric Co., Ltd. is a high-tech enterprise dedicated to the development and production of electrical equipment and numerical control equipment. After years of hard work, it has now developed into a large-scale company integrating R&D, design, manufacturing, sales and after-sales. Enjoy a high reputation.

Since its establishment, the company has always adhered to customer-centricity, and has taken every link of R&D and production seriously. Our staff are extremely responsible, carefully researching and developing manufacturing equipment, adhering to a rigorous and scientific attitude to ensure the performance of every equipment produced Superior, reliable quality, stable operation.

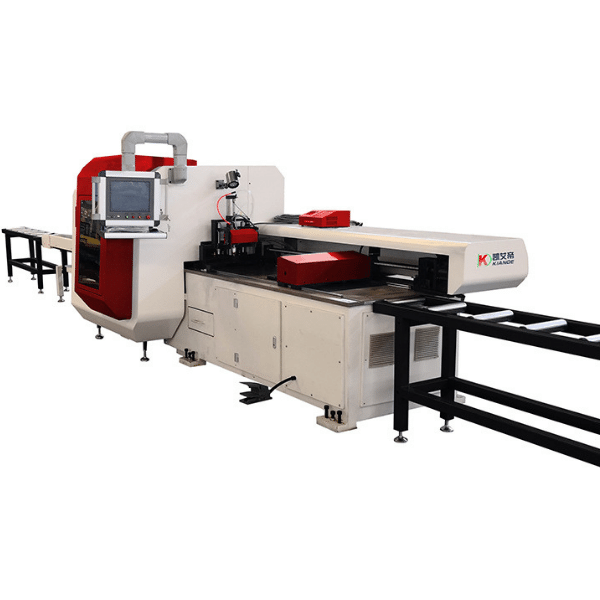

Cnc Bending Machine Recommend Products

Cnc Bending Machine Detail Introduction

CNC bending machine is considered essential in all machining and manufacturing industries since it saves much time and performs long-lasting bending. In fact, unlike other machines, this machine can be used without any additional tool or assembly. Hence, this specific machine has been introduced to strengthen the production line of various manufacturers across the globe.

1.What is CNC bending?

CNC bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal. Commonly used equipment includes box and pan brakes, brake presses, and other specialized machine presses.

Typical parts are brackets, frames, rails, and beams. The sizes can range from small (e.g., for bracelets) to very large (for example, for the roof beams of an airplane).

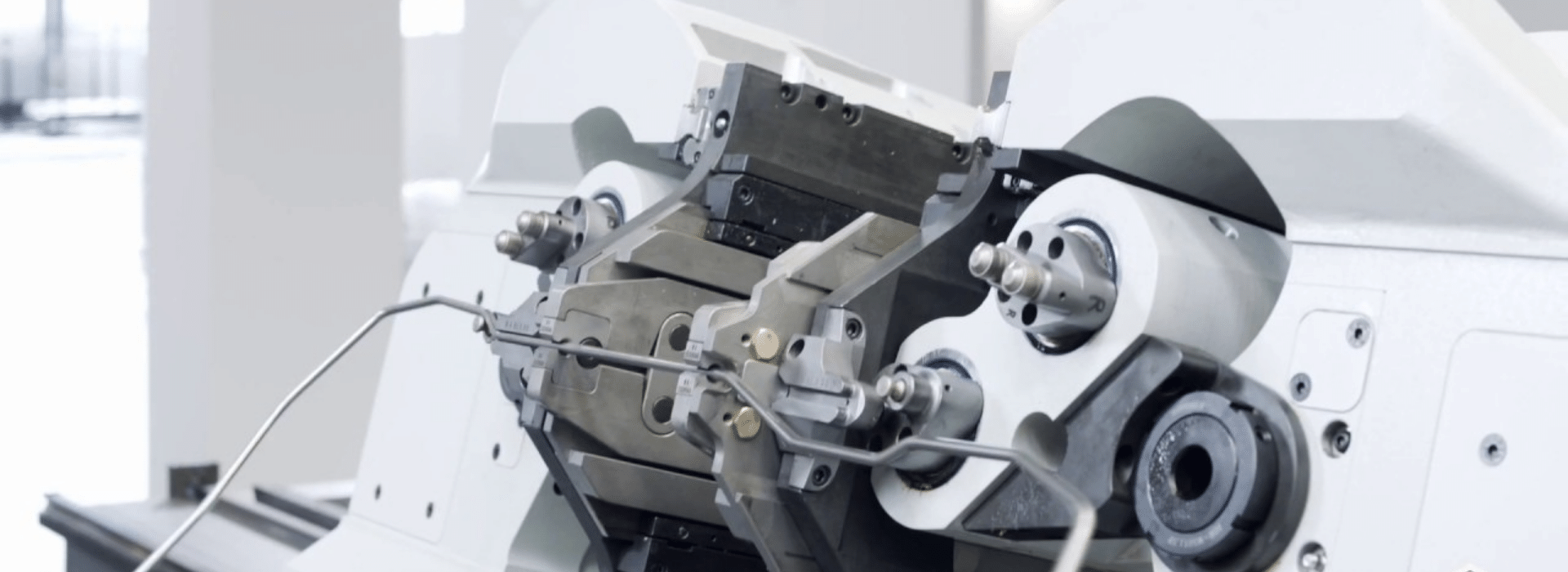

The tooling is fixed in the CNC bender machine (not moved during the operation), and the workpiece is moved between operations. The workpiece is held in place with clamps mounted on movable arms. These arms move together with the workpiece while it is being bent.

2.What is the working of the CNC bender machine?

The CNC bender machine is a kind of automatic pipe bending machine. The mold can bend the workpiece. The whole process is completed automatically by the servo system and PLC program control. The machine has two single pipe bending and multi-pipe bending functions, which meet users' needs for different pipe bending processes.

The working principle of the busbar bender machine is roughly divided into two parts:

(1)Manual control: manual control of the device is the main auxiliary control method of the automatic control system. It is mainly used in debugging phase and emergency stop; if not necessary, it should not be used.

(2)Automatic Control: Automatic control of equipment by computer according to process requirements, using PLC as core, using servo or stepper motor as actuating device, using the sensor as an input unit, using relay contactor or solid-state relay or inverter as a power switch device, and using communication interface (such as field bus) to communicate with a host computer so that the whole system can achieve automation management and monitoring.

3.What is the function of the CNC bending machine?

CNC bending machine is one of the main equipment for manufacturing high-precision controlled complex curved pipe parts for aviation, aerospace, electronics, and other industries. It can realize the multi-axis linkage processing of various bending shapes of straight pipes. It can be bent into various shapes such as circular arc, elliptical arc, spiral arc, and polyline arc in three dimensions.

After years of research, the CNC pipe bending machine is the latest product developed by our company. The machine has a high automatic degree and productivity, advanced structure design, convenient operation and maintenance, good processing quality, complete function, high reliability.

Main Features:

(1)The numerical control system adopts a PLC programming controller with color LCD, which is easy to learn and operate.

(2)Hydraulic cylinder drive ensures accurate stroke length and smooth operation;

(3)The use of a full hydraulic pressure clamping device makes holding force more reliable;

(4)Equipped with pneumatic pressure counter device to ensure safety;

(5)Equipped with bending data memory device (optional), which can store up to 20 sets of bending data;

(6)Equipped with optical encoder to calculate the processed tube length (optional);

(7)The oil cylinder has a quick opening

4.Different Types of CNC Bending Machines

Various CNC bending machines can be used for bending and cutting metal. Various types of material can be used depending on the project. Types of Bending Machines:

1.Metal sheet bending machine

A metal sheet bending machine, also known as a press brake, is a common metal forming machinery. It has the advantages of high precision and fast speed. It can process various kinds of sheet metal, especially in automobile manufacturing, electric cabinets, and elevator industries.

A metal sheet bending machine can bend the panel into various angles and shapes by changing different molds. Usually, the mold is installed on the bending machine by bolts.

Steel bending machine suppliers have developed a CNC metal sheet bending machine to improve efficiency. This machine can automatically adjust the mold according to the parameters required in the production process without manual intervention. Thus it can greatly improve the precision and efficiency of metal panel processing.

The automatic metal sheet bending machine is an automatic CNC drive flywheel type, one-time completion of the sheet into the molding process. Using a special fixture to complete the different shapes of the workpiece. The device has a programmable controller (PLC) and touch screen control, easy operation, simple maintenance, and a high degree of automation. The machine is suitable for bending all kinds of sheet metal into various geometric cross-section workpieces, widely used in electronics, electrical appliances, lighting, lamps and lanterns, advertising signs, and other industries.

2.CNC wire bending machine

CNC wire bending machine is the extension of the concept of CNC wire bending machines. It is suitable for the mass production of standard parts. With the development of science and technology, the CNC wire bending machine has gradually replaced ordinary wire bending machines, becoming a new trend of wire processing machinery.

CNC wire bending machine is a kind of metal material special processing equipment which can make all kinds of metal materials such as metal rods, metal wires, or metal tubes into different shapes by an external force. The main function is to use the relative movement between the workpiece and the mold to deform the workpiece, thereby obtaining various shapes that meet the requirements. With the rapid development of China's economy and technology, it has been widely used in various industries and fields. It has become essential industrial equipment for manufacturing and production.

3.CNC pipe bending machine

A pipe bending machine is a kind of pipe processing equipment with high processing efficiency and is easy to use. It can process pipes with different diameters and different wall thicknesses. The pipe bending machine is equipped with a numerical control system and a hydraulic system, which can adjust the pipe bending radius. The pipe can be bent into various shapes.

The automatic pipe bender machine has stable performance and high efficiency. It has the advantage of fast clamping and high accuracy. The maximum diameter of the processed pipe is 220mm, the maximum wall thickness is 15mm, and it can process carbon steel, stainless steel, and other materials. The automatic pipe bending machine adopts a numerical control system to achieve accurate positioning of bending Angle and reduce labor intensity.

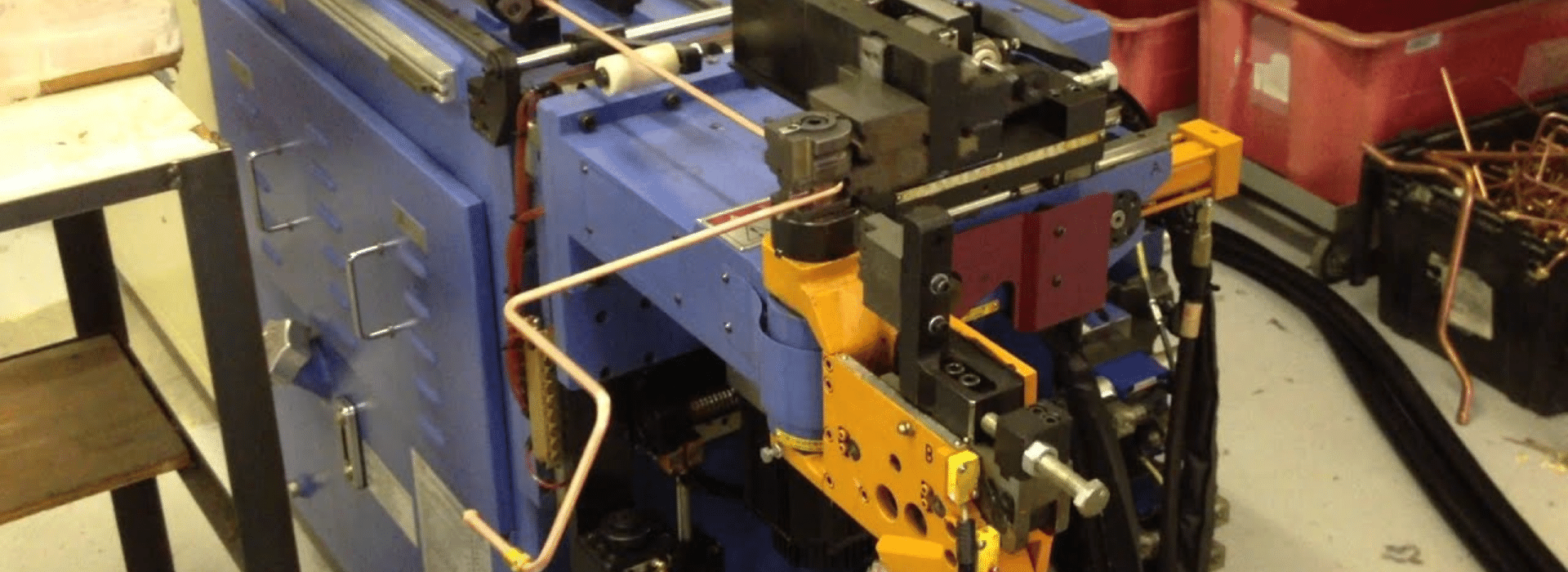

In particular, the demand for copper bending machines is very great!

A copper bender machine is a device that will bend copper tubes or pipes in a particular direction and shape. Copper pipe bender is commonly used for water supply lines, refrigerant lines in HVAC systems, and various other applications in the construction industry. All such tubing is designed to hook up rigidly at each end so that water can flow through it without difficulty. The process of bending copper tubing is simple but must be done carefully to prevent damage to the tubing itself.

There are several different types of copper line bender available on the market. In some cases, the design of a copper bending machine allows a user to select from a variety of different bends with preset angles and radii. In other cases, a machine might be programmable so that users can enter their specifications for custom bends.

4.Hydraulic busbar bender

Hydraulic Busbar Bending Machine, also called hydraulic busbar bender, is a powerful bending machine for processing copper and aluminum busbar. It is one of the essential pieces of equipment for the power industry and electrical engineering. The hydraulic bus bar bender has excellent performance and high efficiency. It can bend flat bars, square bars, and round bars according to your different needs.

The small hydraulic bending machine is used for bending metal sheets into a required shape. The machine is widely used in metalworking, and it can also be used for chassis shells, metal boxes, instruments and meters, and other processing. With high performance and competitive price, our products are well received by customers all over the world….

5.What is the application of a bending machine?

CNC bending machine is a kind of CNC machine tool suitable for processing all kinds of sheet metal parts in the production process can be completed by a molding process, bending and straightening; there are two kinds of CNC bending machine: plate bending machine and Angle bending machine.

The CNC bending machine is widely used in automobiles, motorcycles, electric power, chemical industry, shipbuilding, aviation, and light industry. In the field of transportation, the chassis and body shell of cars, motorcycles, and high-speed subways use large quantities of sheet metal parts. The large air ducts used in ships are also sheet metal parts. The application of the CNC bending machine can improve production efficiency and product quality, reduce labor intensity and production cost, and is gradually being promoted.

6.How to use the bending machine?

An automatic bending machine is also called an NC bending machine. It is a numerical control bending equipment with high efficiency, precision, and good stability.

(1)Before using the CNC bending machine, we must check whether all parts of the NC bending machine are in good condition whether the fasteners are loose or not.

(2)If it is the first time to use the automatic bending machine, it should be checked after power on for about one hour. The error of each deformation system should be adjusted according to the requirements of technical parameters.

(3)Check whether the pedal switch and the handle are flexible and reliable before using NC press brake

(4)When using an automatic bending machine, it is necessary to pay attention to whether there is any abnormal sound in all parts of the NC press brake, especially when starting up and slowing down, whether there is any abnormal sound in each part of CNC press brake manufacturer.

(5)After every shift of the automatic bending machine, it is necessary to clean up all kinds of sundries on the working surface of the NC press brake and add lubricating oil where lubrication is needed.

(6) To ensure safety, you must shut off the power supply when you leave your seat during work or maintenance operation

7.Bending machine Care and Maintenance

Your bending machine is an important tool that you use every day. To keep it running smoothly and efficiently, you need to care for it properly. Here are some tips for bending machine care and maintenance.

(1)Check whether there is any damage or deformation in the appearance of the busbar machine before use. If there is any, do not continue to use it;

(2) Check whether there is water in each oil tank of the busbar machine before starting up; if there is no water, add water according to the specified amount;

(3) Check whether the pressure value on each pressure gauge is stable and within the normal range;

(4) Check whether all buttons on the control panel are normal and operate normally;

(5) Turn on the power switch and press the start button; if you hear any abnormal sound from inside or outside, you need to cut off the power supply and check it out immediately;

(6) When using for a long time, remember to add lubricating oil regularly to ensure that there is enough lubricating oil in each part of the busbar machine

8.Bending machine manufacturers providing total solutions

Today, the rise of bending machines has become the most prominent development. It has a wide range of applications for bending machines in many fields, such as light industry, machinery, metallurgy, transportation, etc. The bending machine manufacturer's product manufacturing technology is constantly improving, making its products more and more sophisticated.

Nowadays, bending machines have been widely used in various industries, such as light industry machinery factories; bending machine manufacturers are very popular with domestic and foreign customers! Its products have been widely exported to foreign countries and recognized by customers abroad! The products produced by various bending machine manufacturers are also different in quality and price. Some manufacturers produce low-quality products at low prices. Users should not only pay attention to the price when buying equipment. It is also necessary to consider whether its performance is stable enough when choosing a professional CNC pipe bender supplier for purchase. At present, our country has produced many excellent CNC pipe bender suppliers who can produce high-quality automatic bending machines.

Bending machine manufacturers providing total solutions for your needs, Kiande is one of China's leading suppliers of bending machines.

9.How can I choose a suitable bending machine?

There are many bending machines on the market, but how do you choose a suitable bending machine? According to the production needs, choosing the right bending machine is necessary.

(1)To produce homogeneous products, it is best to use a hydraulic bending machine. Because of its high degree of automation and high production efficiency, the processing accuracy is also higher. But this kind of equipment price is relatively high.

(2) You can use a CNC bending machine or an electric bending machine for small batch production. This kind of device is easy to operate and has a wide range of uses. The cost performance is also very high.

(3)Some other models have their characteristics and characteristics, such as hand-rolled machines, induction heating benders, etc., according to their situation to buy.

10.Bending machine FAQ

1.Can I cut with a bending machine? (press brake)?

Yes, you can use the press brake to cut, but there is no guarantee that it will be as accurate and efficient as a shear. The bending machine works with lower clearance and can cause problems with the cutting blade if you don't set the punch correctly. Also, not all bending machines have a cutting blade.

2.How to bend a pipe into a circle?

You can use a pipe bender to bend it.

It is impossible to make a perfectly circular bend, but that is not always necessary. If you want a circular bend, you will have to do it in several steps, making one bend at a time.

3.What type of motor is used in a pipe bending machine?

"The motor used in a pipe bending machine is a 2 HP 3 phase 1420 RPM motor. The pipe bending machine consists of three main parts, the electric motor, gearbox, hydraulic unit, and the bending arm. The hydraulic unit consists of a hydraulic pump, a cylinder, pressure gauge, and valves. The bending arm consists of a fixed handle, a moveable handle, and a die block.

4.How hydraulic system works in CNC machines?

The hydraulic system of the CNC machine tool is mainly used to provide pressure and flow for the transmission part of the machine tool. It can realize the mechanical motion required by the NC part program to achieve automatic machining.

5.What is a Copper U bend Machine?

Copper U Bend Machine is our company's professional bending equipment suitable for all kinds of tubes. The bending degree is flexible and can be adjusted freely.

It can also provide customers with free bending services because we have many years of experience in this field and are well versed in the production process and requirements of copper tubes. We can provide customers with more professional help.

11. About Suzhou Kiande Electric Co., Ltd.

Suzhou Kiande Electric Co., Ltd. has advanced management experience, strong technical force and strong sales network. The company's main products are at the leading level in the domestic industry. The company has excellent production equipment, advanced and reasonable technology, and strong technical force. In the market operation, we always pursue the goal of first-class technology, first-class products, and first-class service, and seek development through continuous innovation.

Our products are mainly dedicated to standard bus bar processing machines, economical copper bar processing machines, CNC bus bar processing machines, CNC bus bar bending machines, CNC turret bus bar processing machines, CNC copper bar processing machines, combined bus bar processing machines , Production and sales of portable bus processing machines and other products.

We have rich production experience and enjoy a very high reputation in the international market. Our products are first-class in terms of quality and performance. If you need it, you can contact us and we will provide you with a satisfactory answer.

12. Our advantages

(1) We can design according to customer's requirements.

(2) We can do OEM according to customer's requirements.

(3) We can provide you with high quality at the most competitive price.

(4) We can provide you with good after-sales service.

(5) We have a strong professional technical team.

(6) We can deliver the goods within 7-20 days after receiving your deposit.

13. Our service

(1) Pre-sales: We will give you professional guidance to help you choose the right machine. After you choose our machine, you can get the most profit by using our machine.

(2) Sales: We will feed back your order information through photos and videos, so you can rest assured.

(3) After-sales service: We will go to your factory to give you training and teach you how to use our machine, or we will give you video training. If there are our local agents and offices, we will send our local engineers to your factory and provide you with training. To

(4) Our quality assurance: All our machines are verified layer by layer, the quality is very reliable, and the service life is very long. To

The busbar processing production line has excellent performance in many aspects, avoiding the shortcomings of traditional processing methods, and has realized very well in terms of quality and performance. Its appearance has brought great convenience to processing plants and brought us to our lives. There are a lot of benefits and good development prospects.

After reading the above content, you must have a full understanding of the busbar processing line. If you have any needs in this regard, or if you have any questions, you can contact us at any time. Our staff will answer your questions one by one. If you want to purchase equipment, we will also provide the most reasonable price and the best quality service, and look forward to working with you to achieve a win-win cooperation.