Suzhou Kiande Electric Co., Ltd. is a professional enterprise integrating R&D, production and sales. It has more than ten years of rich experience in the electrical field. Wood Pallet Making Machine developed and produced has been obtained in the domestic and foreign markets. Received a very high evaluation and became one of the world’s leading manufacturers.

We are China Wood Pallet Making Machine manufacturers and suppliers. We have a productive factory at your service. Please rest assured to buy the quality equipment made in China from our factory.

Wood Pallet Making Machine Recommend Products

Wood Pallet Making Machine Detail Introduction

Wood pellet making machine complete details - offered is a wood pallet making machine that produces various sizes, shapes, and specifications of wooden pallets. Crafted completely in this industry, our wood pallet-making machine utilizes the most state-of-the-art technology.

What is a wooden pallet-making machine?

Wooden Pallet Making Machine is wood pallet manufacturing equipment to make wood pallets. With the development of the world economy and trade, more and more countries are opening up their markets to the world; hence international trading has constantly been developing in recent years, especially the exporting and importing among the different countries. The wooden pallet is one of the basic products used in this field. China is a country with large industrial-strength, especially concerning the manufacturing industry, so it has exported various kinds of wooden pallet-making machines to some countries in Europe at present.

History of Wood Pallet Making Machine

The history of wood pallet maker making machine is a long and interesting. The first wooden pallet was documented in Ancient Egypt as early as 3500 BC. It could be said that it all started there, but for the sake of brevity, and to make this article about a topic other than Ancient Egypt (as interesting as it may be), we'll stretch the truth and say that the first wooden pallets weren't documented until 1907 with foundries using them to move large iron castings around their factory.

How does Wood Pallet Making Machine work?

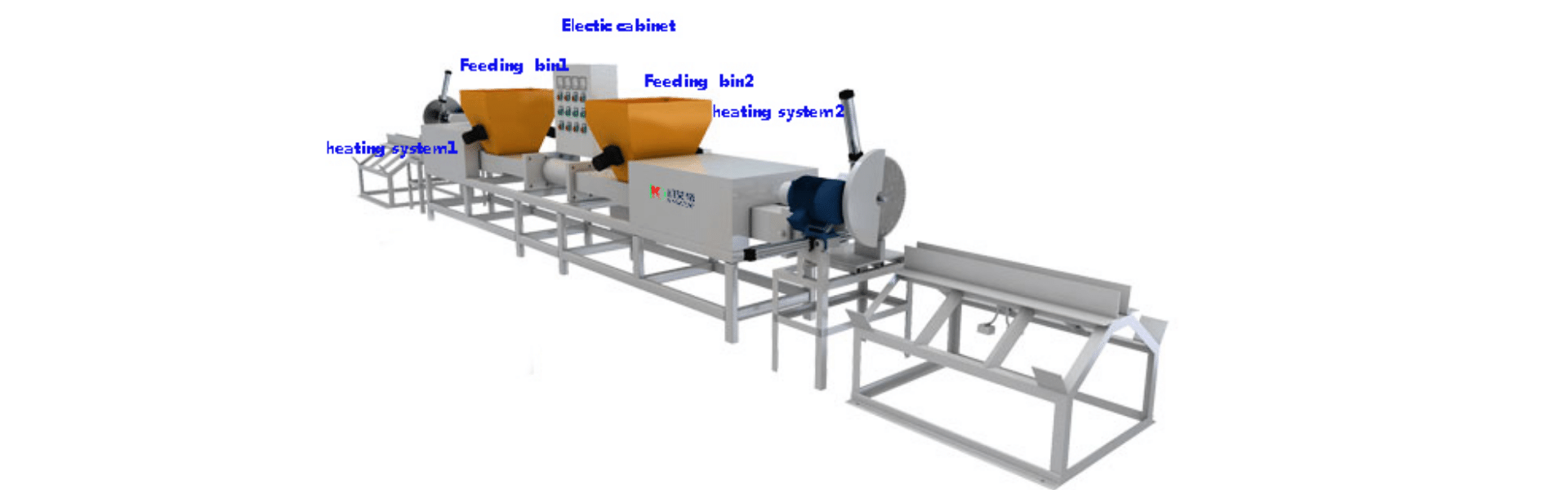

Production steps of automatic wooden pallet-making machines differ with this equipment's different types. Generally speaking, it includes preparation for raw materials, forming molding, and components.

1. The wood pallet-making machine consists of the following components: chain conveyor, cutting machine, automatic nail gun, hot stamping machine, and stacking conveyor.

2. First, the woodblock is placed on the chain conveyor, and then the chain conveyor will transport the wooden block to the cutting machine.

3. Then, the cutting machine will cut the wooden block into two equal parts.

4. Next, these two parts are transported to the automatic nailing device separately through two chain conveyors.

5. Then, the automatic nailing device will nail them together to form a wooden board.

6. After that, these boards will be transported to the hot stamping device through another chain conveyor for hot stamping treatment.

7. Finally, these hot-stamped wooden boards will be stacked on top of each other through a stacking conveyor to form a wooden pallet.

What are the types of Wood Pallet Making machines?

There are many types of wood pellet making machine. They are classified based on the manufacturing process they follow, by type or size of pallets they make, or on the usage, these machines are employed for. A popular option is to decide the type of pallet you want to make and then find the right machine to make that kind of pallet.

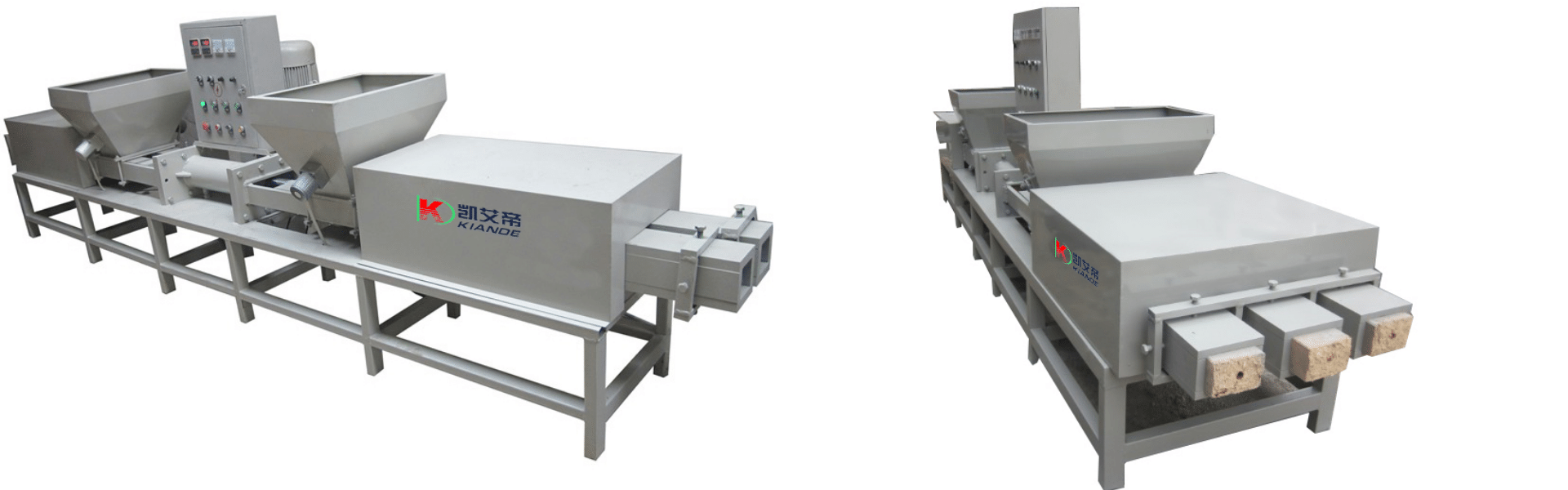

Sawdust wood pallet blocks making machine

Sawdust Wood Pallet Blocks making machine is a pallet recycling machine. It is developed for small and medium-sized enterprises with large quantities of waste wood pallets to process. The main parts of the wood pallet block making machine include feeding device, block-cutting device, wrapping rubber bands device, and feeding table.

Automatic wooden pallet making machine

The fully automatic pallet making machine is a device that can make high-quality wooden pallets that are easy to break down, transport, store, and load. It also makes it easier to store various goods during transport thanks to the standard dimensions of pallets, but it is much more efficient than traditional wooden pallets. It is appreciated in the market due to its low price and efficiency.

Compressed wood pallet making machine

A compressed wood pallet making machine is the processing of green timber boards or wooden logs. The manufacture of wood pallets can be made from either solid wood, wood chips, or a combination of both.

Compressed wood pallet making machine is one of the most popular and commonly used machines in our industry. This machine is widely applied in large, medium, and small enterprises. The compressed wood pallet machine is greatly used for various purposes.

Bamboo pallet making machine

A bamboo pallet making machine is a device used in various kinds of manufacture and production lines, transport, loading and unloading operations, use of the palletized load. They make up their kind of mobile heavy machinery equipment. It is not just the use of primary wood sundries, semi-finished products (such as plywood), and the finished product, etc. pallets, pallet production line moves its running job.

Food pallet making machine

food pallet making machine This is used to press food pressure packing. We are a professional production of food equipment company. For us, technology is always ahead of the times, ensuring that we deliver a high-quality product.

Main components of pallet making equipment

Pallet manufacturing equipment is widely used for pellet making production line and need to be installed in the whole production line. I will introduce the main components of pallet making equipment to you, I hope it can help you select the right one.

Pallet notching machine

The pallet notching machine is employee-friendly; it has a long shelf life. It has many advantages and few shortcomings. This machine is not only simple in operation, it also can save time labor cost, and improve work efficiency. The pallet notching machine we produce can be used in various industries and has got CE certification.

Sawdust block press machine

A sawdust pallet block making machine is used for cutting logs of wood into blocks. To cut blocks from larger logs of wood, a machine is required. The design of the machine is such that two circular shafts are used. The two shafts help hold down the sides of the log firmly as it undergoes the cutting process.

Wood Block Cut Saw Machine

This woodblock cut saw machine is used to prepare the building blocks out of plywood, MDF,etc. Cutting blocks are used for both exterior and interior applications. The roller carriages increase the stability and smoothness of the cutting process. The sawing machine provides two-way rotation for convenience for 360-degree cutting.

Pallet building machines

Pallet building machines build modular wooden pallets for efficient and reliable shipping of your products. Pallets are used to ship various products from household goods, auto parts, and even food. An increasing number of people prefer using pallet building machines for manufacturing their custom-made wooden pallets.

What are the advantages of a Wood Pallet Making Machine?

A wood pellet making machine is a kind of wood processing equipment that can process wood into wood pallets or wood packaging. The wood pallet produced by the wood pellet making machine has a high utilization rate, low cost, saving resources, and reducing transportation costs.

The advantages of wood pellet making machines are as follows:

1. It is widely used and has a wide range of materials. It can be used to make wooden pallets, wooden packaging boxes, and other products with different specifications and shapes.

2. It has many functions, multi-function and multi-use. One machine is equivalent to several single equipments, which can reduce investment costs for users; it can also save space for users; because it is made up of several single pieces of equipment. Therefore, it saves labor force for users; the use effect is good, which can increase production efficiency and reduce production costs for users; it is easy to operate and has a low failure rate, so it is convenient to maintain and repair; the operation of this equipment is safe and reliable, so it can improve work efficiency and reduce labor intensity for workers.

3. It has good performance and simple operation, with reliable quality and convenient maintenance

What are the disadvantages of a Wood Pallet Making Machine?

1. The disadvantage of wood pallet making machines is that the use cost is high and the production efficiency is low. The pressure of forming mold is mainly provided by the mechanical transmission device, which has higher energy consumption and lower production efficiency.

2. The disadvantage of a wood pellet making machine is that the equipment is bulky, and the space occupied by the equipment is large, so it needs to be equipped with a dedicated production line. In addition, due to the large size of the equipment, it is difficult to move, so it is difficult to renovate or adjust the production line.

How much is a Wood Pallet Making Machine?

Wood pallet making machine prices vary based on the brand and model and the conditions of purchase. The price can also vary depending on where you live and where the sale is being made. If you are looking to purchase a wood pellet making machine with basic functionality, you should expect to pay anywhere from $3,000 up to $15,000.

Our company specializes in wood pallet making machine for sale, welcome to consult.

Wood Pallet Making Machine VS plastic pallets making machine

1. Different materials, different advantages

Wood pellet making machines use wood as raw materials, and plastic pallet making machines use recycled plastic as raw material.

The advantage of the wood pellet making machine is raw material cheap, but the disadvantage is short service life. The advantage of a plastic pallet making machine is its long service life, but the disadvantage is the high cost.

2. Different manufacturing processes, different features

The process of wood pellet making machine is simple and low cost. The process of plastic pallet making machines is complex and high cost. Plastic pallets are more beautiful than wood pallets and have better stability. Here you can see the demonstration video of the plastic pallet production process:

3. Different applications, different uses

Wood pallets are widely used in industries that do not require strict hygiene standards and are not afraid of insects or water damage. Plastic pallets are widely used in warehouses and factories that require higher hygiene standards or have certain water content requirements (such as food/beverage industry).

How to choose a quality wood pallet making machine suppliers?

Here are some tips for choosing a quality wood pallet making machine supplier.

1. Choose a supplier with years of experience in the wood pallet machine industry. The company must have a good reputation and credit to be sure that the supplier will not run away if there is something wrong with the machine.

2. See whether the supplier has their factory to manufacture machines. If they are just a trading company, most will not provide after-sale service for customers.

3. Visit their factory and see whether it is professional or not and whether the workers have a good working attitude.

4. Inquire about their services, including installation, training, after-sales service etc., these are very important for long term cooperation.

5. Inquire about handling disputes if there is any between supplier and customer.

About Suzhou Kiande Electric Co., Ltd.

Suzhou Kiande Electric Co., Ltd. has advanced management experience, a strong technical force, and a strong sales network. The company’s main products are at the maximum level in the domestic industry. The company has excellent production equipment, advanced and reasonable technology, and a strong technical force. In the market operation, we always pursue the goal of first-class technology, first-class products, and first-class service and seek development through continuous innovation.

We have rich production experience and enjoy a very high reputation in the international market. Our products are first-class in terms of quality and performance. If you need it, you can contact us, and we will provide you with a satisfactory answer.

Our advantages

(1) We can design according to customers’ requirements.

(2) We can do OEM according to the customer’s requirements.

(3) We can provide you with high quality at the most competitive price.

(4) We can provide you with good after-sales service.

(5) We have a strong professional technical team.

(6) We can deliver the goods within 7-20 days after receiving your deposit.

Our service

(1) Pre-sales: We will give you professional guidance to help you choose the right machine. After choosing our machine, you can get the most profit by using our machine.

(2) Sales: We will feedback your order information through photos and videos so that you can rest assured.

(3) After-sales service: We will go to your factory to give you training and teach you how to use our machine, or we will give you video training. If there are our local agents and offices, we will send our local engineers to your factory and provide you with training.

(4) Our quality assurance: pallet making machine china are verified layer by layer, the quality is very reliable, and the service life is very long. To

The wooden pallet making machine has an excellent performance in many aspects, avoiding the shortcomings of traditional processing methods, and has realized very well in quality and performance. Its appearance has brought great convenience to processing plants and brought us to our lives. There are a lot of benefits and good development prospects.