Suzhou Kiande Electric Co., Ltd. is a professional enterprise integrating R&D, production and sales. It has more than ten years of rich experience in the electrical field. The Robot Welding Machine developed and produced has been obtained in the domestic and foreign markets. Received a very high evaluation and became one of the world’s leading manufacturers.

We are China Robot Welding Machine manufacturers and suppliers. We have a productive factory at your service. Please rest assured to buy the quality equipment made in China from our factory.

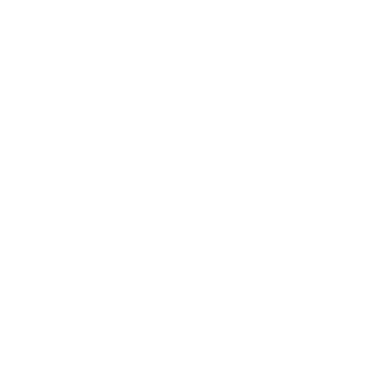

Robot Welding Machine Recommend Products

Robot Welding Machine Detail Introduction

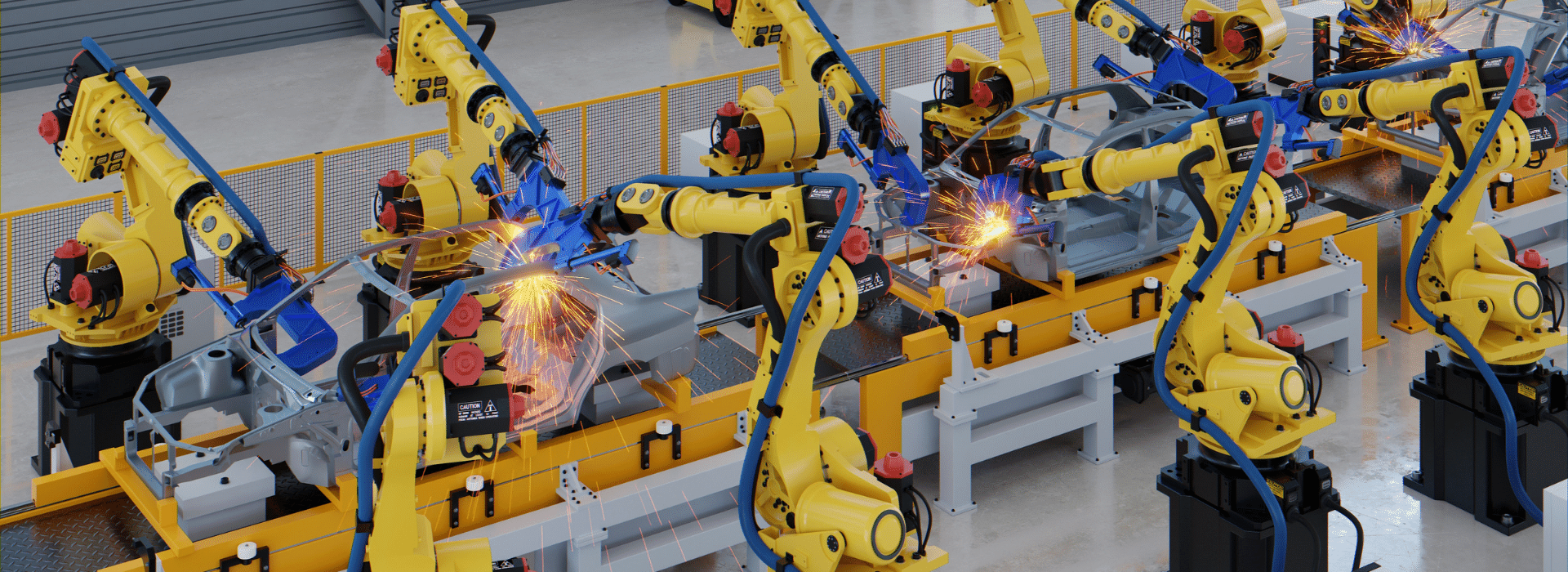

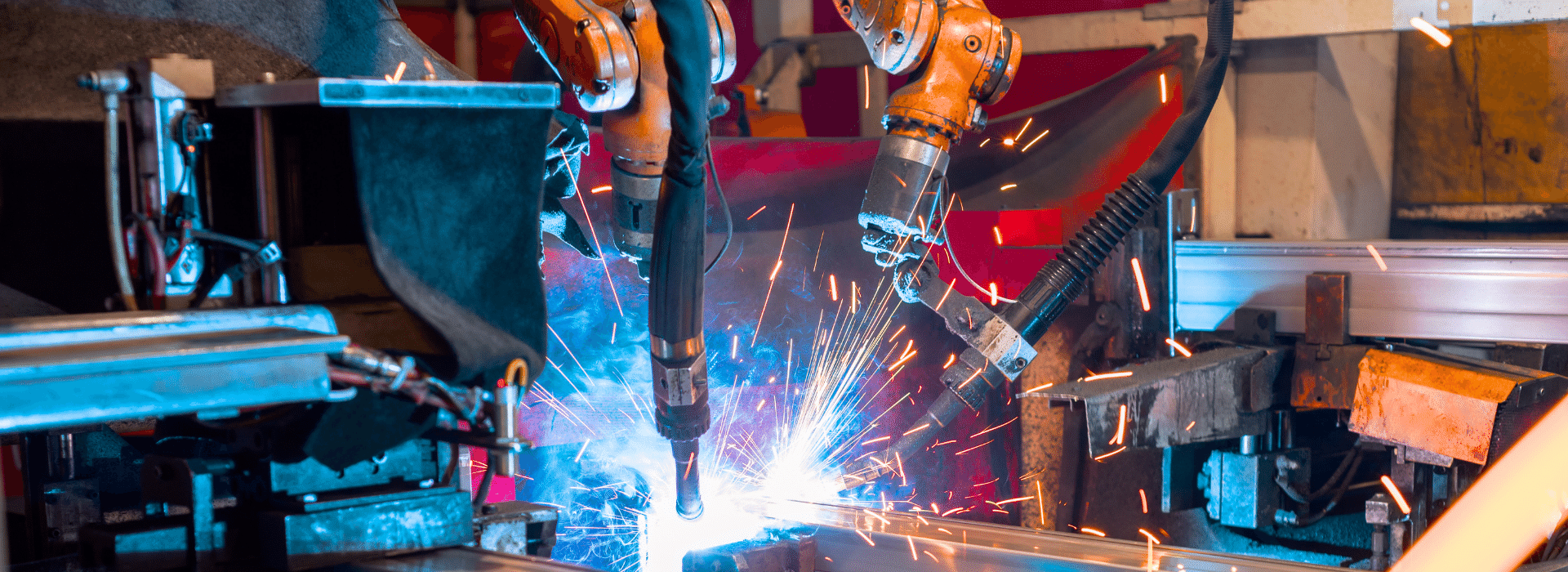

The robot welding machine is the heavy-duty equipment that is used for welding. As the name suggests, it can do the jointing work of steel with consummate perfection. This robotic equipment can weld any size of machinery at one go. To do this flawless job, there have to be some prototypical qualities like strength, durability, and precision. These are some of the most important aspects to be considered while buying this remarkable piece of machinery.

You will find out some interesting information about the automated welding robot machine. I have collected some useful information about the robot welding machine, and I am sure that after reading this post, you will be able to decide what is right for your needs.

1.What is Robot Welding Machine?

The CNC robot welding machine is a type of welding machine that uses robots to complete some welding operations. The robot can be programmed to perform complex tasks and repeat them with high speed and accuracy. A computer system controls a robotic welder, which receives input from sensors and digital programming and transmits commands to the robot arm, head, or other components.

Robot welders are widely used in automatic welding production lines, assembly lines, pipeline welding, and other semi-automatic or automatic welding fields.

2. Robot Welding Machine development history

The history of Robot Welding Machine is mainly divided into three stages:

1. The first stage (1950-1965)

The birth of the world's first Robot Welding Machine, Electroimpact, is a milestone in developing Robot Welding machines. In 1954, the first generation of industrial Robot Welding Machine was born in the United States. Due to its simple structure and limited application range is called a "mechanical arm" or "industrial manipulator."

2. The second stage (1965-1980)

In 1965, Unimate, made by the United States, was the world's first series-produced industrial Robot Welding Machine. Its successful application in the General Motors stamping workshop has become a milestone event in developing industrial Robot Welding machines.

3. Third stage (since 1980)

In 1980, after nearly 30 years of development and evolution, robot welding machine otc had undergone tremendous changes both in terms of structure and performance. It has developed into a large robot with six degrees of freedom and more than 20kg load capacity. It can realize manual and automatic programming through computer technology and numerical control technology, which greatly improves the flexibility of Robot Welding Machine operation flexibility.

3. How does Robot Welding Machine work?

1. Welding preparation

The operator should check the welding machine and tooling, including whether the power supply meets the requirements, enough gas in the cylinder, and whether the gas pipeline and contactor are firm. The welding machine should be placed in a suitable position for easy operation.

2. Fixing the processing parts

The processing parts to be welded are fixed on a jig with a clamp or a suitable fixture according to the shape of the processing parts. The fixture is important for ensuring welding quality and reducing labor intensity. In addition: pay attention to safety protection when installing the jig, especially the installation that involves personnel operations.

3. Robot Welding Machine Operation

Turn on the main power switch of the otc robot welding machine and start it up normally; press "Start" switch on "Main Control Panel" to make robot programming run automatically; adjust "speed" control knob on "Welding Control Panel" can control robot arm speed; switch "Air Switch" button can control robot arm movement; press and hold "Emergency Stop Button" can stop all actions of robot arm immediately in case of emergency; long-press "POWER OFF BUTTON" can shut down all power supplies at once in case of emergency.

4. An important part of Robot Welding Machine

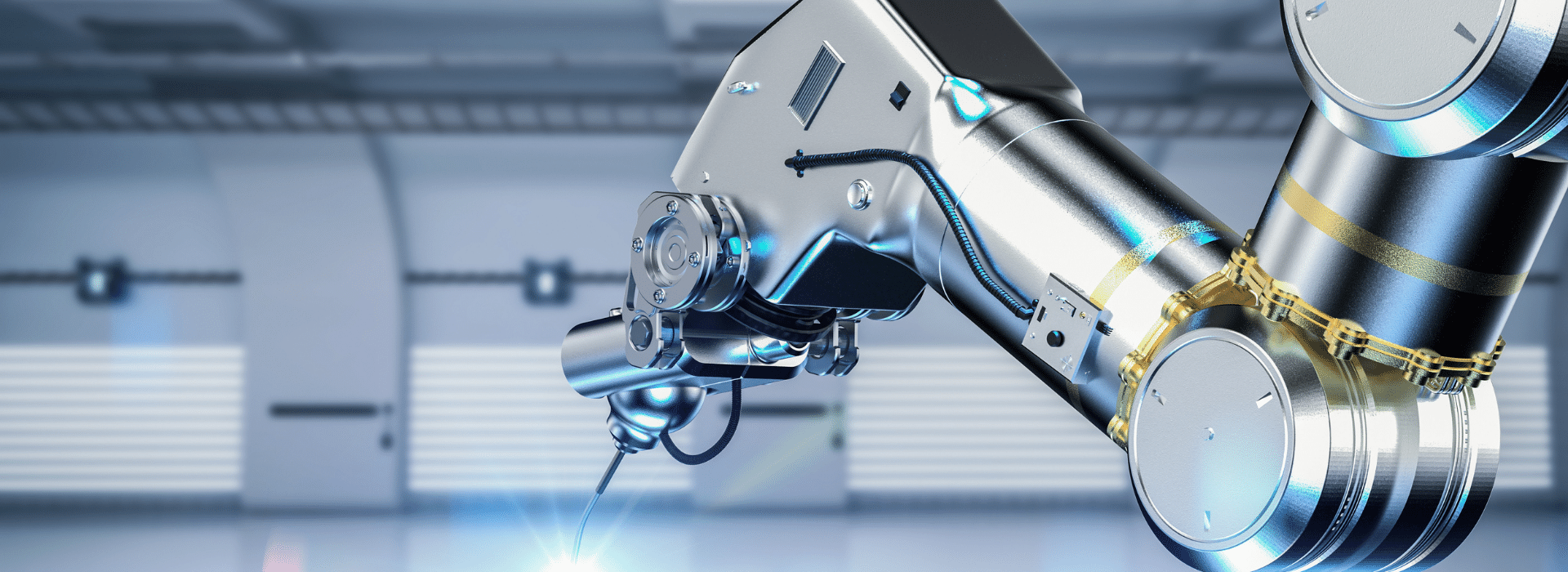

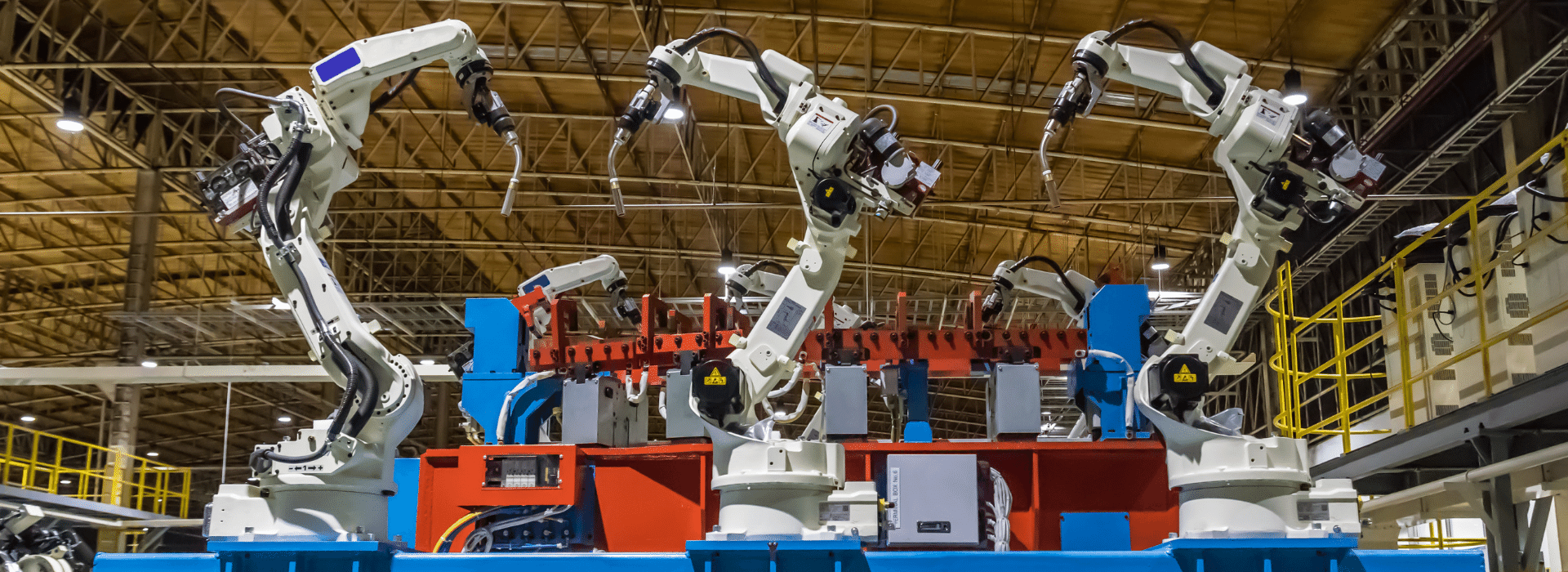

The robot welding machine is a multi-degree of freedom automatic welding equipment. The main difference is that the robot can realize the three-dimensional movement in space so that the robot can be installed on the linear slide rail for welding at any angle and any point in space.

Robotic arm welding machines are mainly composed of arms type, motion control system, and auxiliary system.

Robot arms play a role in supporting and supporting robots. Robot arms are generally made of high-strength metal materials, which can move freely within a certain range of space. Robot arms also have different structures according to their functions.

The motion control system mainly comprises an electric drive unit and a control device. The electric drive unit mainly consists of servo motors, reducers, and other components, which provide power for the action of the robot arm. The control device is mainly composed of the CPU (central processing unit), a driver circuit, and other components, which controls each component of the robot arm through programming instructions or manual manipulation to complete various welding processes.

The auxiliary system mainly includes external manipulators and arc torch sensors. External manipulators are used to manipulating external tools to perform various operations on workpieces outside the workspace, such as clamping workpieces or changing tools.

5. What are the types of Robot Welding machines?

Robot welding is a process that uses industrial robots to weld parts together. The welding machine will be programmed to move in a specific path and weld the parts according to the desired specifications. There are many types of welding robots available.....

1. Robotic laser welding machine

The robotic laser welding machine uses a high-energy heat source to melt the workpieces and weld them together. The laser beam is delivered from an optical system to a workpiece from a laser source. After passing through the surface, it is absorbed and converted into heat energy that melts the material. The molten material flows together and solidifies after cooling down to form a welding seam, which achieves the purpose of welding.

Laser welding automation has many advantages: high welding speed, beautiful welding seam, less thermal deformation, and small heat-affected areas. It can be used in automobiles, motorcycles, watercraft, electric power, air conditioner, refrigerators,s, and food machinery.

2. Robotic MIG welding machine

The robotic MIG welding machine is a semi-automatic process that can attach metal parts. The robotic arm is programmed to move the MIG welder along the joint of the two parts. This is most commonly used with steel and aluminum, but other metals can also be welded with this process.

The robotic MIG welder is attached to a robot arm, which makes it possible for the robot to perform various tasks while they are in operation. Some tasks include sweeping, tacking, welding, and buffing. This makes it ideal for large jobs that need to be completed quickly since the robot can perform several tasks simultaneously.

MIG welding automation can be used on various materials, including carbon steel, stainless steel, and aluminum. They can use different power sources depending on the type of material being welded and the thickness of the material being welded.

The robotic MIG welder uses a high voltage electric arc to heat metal until it melts together. This creates a strong bond between two pieces of metal and makes it more durable than if you were using an ordinary welding machine.

3. Robotic Tig welding machines

Robotic Tig welding machines are great for welding everything from aluminum to copper and titanium, and steel. The process of Tig welding is also referred to as gas tungsten arc welding or GTAW. It is a method that uses an arc with a non-consumable tungsten electrode to produce the weld.

Tig welding starts with the welder using its foot pedal to create the weld. The power source then creates a high-frequency arc between the welded material and the tungsten electrode. As the welder uses the pedal to control the power, a gas shield is created around the workpiece, keeping it from being contaminated by air.

Robotic Tig Welding Machine is used in many different industries, including aerospace, automotive, racing, hydraulic cylinders, and more. Because they are easy to use and there are no consumables required, they are considered one of the most popular welding methods available on the market today.

4. Automated spot welding machine

Automated spot welding machines are widely used for metal sheet welding. Spot welding machines are used in several applications, from home to automotive industries. The most common use of automated spot welding machines is in the automobile industry.

The automated spot welder uses a pair of electrodes that simultaneously pierce the metal sheets and apply current. The current in the electrodes heats up and melts the metal at a specific point, thus joining them together. This process is commonly known as resistance welding since this is an electric resistance process that generates heat by passing a current through two or more closely spaced electrodes.

Spot welding in robotics is important because it reduces human effort and makes the job faster than manual welders, thus increasing efficiency and productivity. They also provide higher quality welds due to consistency in temperature and consistent pressure applied at each joint. The high-quality welds using these machines can be achieved when the right current passes through each electrode.

5. Automated resistance welding machine

Automated resistance welding machines are the highest production equipment at the lowest cost per weld. The automated machine is more efficient, reliable, and consistent than manually operated hand welding machines.

The most common automated resistance welding process consists of a spot welder and a material handling system. This combination is typically called a spot welding robot system. All components of an automated resistance welding machine can be individually manufactured or assembled by third-party manufacturers. They can be purchased as a total integrated system from spot welding equipment manufacturers.

An automated electrical resistance welding works using robotic arms to manipulate workpieces in place for the spot welder to weld them together. A variety of rotary and linear motion material handling systems are available for the transfer of parts to and from the welding machine. Material handling systems can be designed to handle parts based on their geometric features or physical properties such as weight or density.

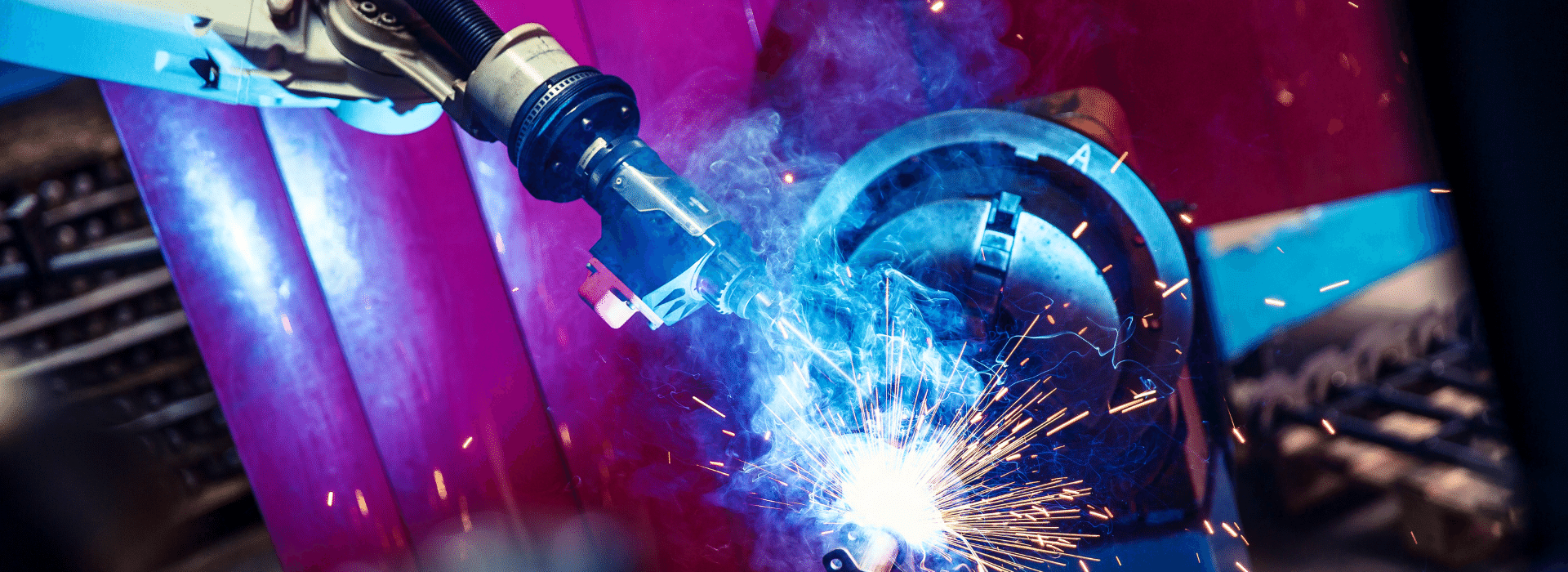

6. Robotic arc welding machine

the robotic arc welding machine is a semi-automatic process in which a specially designed welding head is attached to a robotic arm. The welding arm moves around the workpiece and welds it from different angles in the robotic arc welding process.

Thanks to its six-axis design, this type of automated arc welding machine can be programmed to perform several welding operations. Robot arc welding is used in various industries for tack welding, fillet seam welding, spot welding, and butt jointing.

Robot arc welding is a process in which an electric arc formed between an electrode and the workpiece generates enough heat to melt the base metal and allow for fusion. There are many different types of arc welding processes available, with each having advantages and disadvantages over one another. The most common arc processes include:

*Shielded Metal Arc Welding (SMAW)

*Gas Metal Arc Welding (GMAW)

*Flux Cored Arc Welding (FCAW)

*Gas Tungsten Arc Welding (GTAW)

*Submerged Arc Welding (SAW)

*Plasma Arc Welding (PAW)

6. What are the advantages of a Robot Welding Machine?

A robotic welder is mainly used for welding the appearance parts, and it has a good welding effect. The welding seam surface is beautiful, and the quality is excellent. The weld strength can reach or even exceed the original plate strength. To improve the efficiency of assembly and reduce the cost of production, it is necessary to use robot welding at this stage.

Safety: Computer control system, high degree of intelligence, automatic welding anti-collision protection system, safe and reliable performance;

Welding speed: The speed of robot welding can reach 7-12 times/min (according to different products);

Wide range of applications: Can be used for engineering machinery, automobiles, motorcycles, and other industries.

Environmentally friendly: Automatic adjustment of arc length and current, less splashing of the molten pool during welding process;

Energy-saving: According to different products, the energy-saving effect can be achieved by 50%-70%.

7. What are the disadvantages of robot welding?

Robot welding is a great way to optimize the welding process and increase productivity. But it's not always the right choice. You may think that robot welding is a good solution for your business, but if you don't understand the disadvantages, you could find yourself in trouble down the line.

Here are some of the disadvantages of robot welding:

robotic welders can only be as accurate as their program allows them to be. While this is true with any CNC device, it is especially important to consider when it comes to robots because they are typically used for welding such large parts (think car chassis) that even small inaccuracies can cause problems.

The initial investment can be daunting, especially if you have never worked with robots before and need the training to use them properly and safely.

Robots require more space than other types of welding equipment, such as MIG and TIG welders.

8. What sensors does a welding robot have?

A welding robot has a wide variety of sensors. These include:

* Contact sensor or force sensor, which are used to measure the force applied by the robot. These sensors can detect when the robot is in contact with the workpiece.

* Proximity sensor, which can check if there is an object in the robot's proximity.

* Vision systems, which can locate and recognize objects using cameras.

* Tactile sensor, which measures how hard the tool touches an object and how much torque it applies to it

9. How much is a welding robot?

Robot welding systems range in price from $120,000 to $150,000. Your robot welding system's robotic welding machine cost will depend on the size, payload capacity, reach, part handling capability, and other factors.

In general, robotic welding machine prices of the main components of robots are as follows:

* Robot: about 35%

* Welding power supply: about 30%

* Manipulator: about 15%

* Control system: about 10%

* Remote control system: about 5%

* Anti-collision cage: about 3%

* Other safety facilities and devices: about 2%.

10. What are welding robots used for?

Welding robots are used for various industrial applications, including automotive, aerospace, construction, and shipbuilding. They can be used in both manual and automatic welding processes and manual and automatic cutting processes. Typical welding robots include spot welding robots and arc welding robots.

Welding robots are ideal for high-volume welding or cutting of the same part over and over again. They can be used to make repetitive welds consistent in quality and accuracy, which is not possible with manual labor. Welding robots can also perform difficult welds that would be unsafe or uncomfortable for human workers.

11. What are the advantages of robotic welding over manual welding?

The welding robot system is more accurate and repeatable. It can weld in the same place with the same amount of material every time. This can save money on wasted material, scrap, and rework costs. In addition, it can eliminate operator fatigue problems that cause a variety of weld flaws.

A robotic welding system also frees up operators to work on other tasks within the company instead of performing repetitive tasks such as welding. It also reduces the chance of workplace injuries by removing people from a potentially unsafe area.

12. What is the difference between robotic and automatic welding systems?

Robotic welding systems are automated machines that are used in a variety of applications that require consistent welds. These automated machines can also be known as robotic welding cells and are designed to place welds on the same spot each time accurately. There are two types of automated welding systems, robotic and automatic.

The difference between robotic and automatic is subtle, but it is worth knowing about so you can make an educated decision when purchasing your next automated welder.

Automatic Welding Equipment

Automatic welding equipment is generally simpler than robotic equipment and usually does not require a full-time operator or programmer. It can be left unattended for long periods. Automatic welding equipment consists of a single welding unit, which will generally consist of one or more fixed welding guns or torch heads mounted to an overhead gantry system or similar structure. The advantage of an automatic system is that it provides consistent welds without needing an expert welder. Still, it requires regular monitoring to ensure the quality of the weld remains good and significant downtime for maintenance and changeovers.

Robotic Welding Equipment

Robotic welding systems are what most people think of when they think of automation in general due to their widespread use in manufacturing since the 1970s.

13. How to choose a quality Robot Welding Machine manufacturer?

Looking for a good and reliable Robot Welding Machine manufacturer is always a tough task, especially when so many companies are out there in the market.

Quality

The quality of the product is one of the most important factors to consider while choosing a Robot Welding Machine manufacturer. With that said, we need to ensure that our equipment can operate efficiently with minimal downtime and can withstand harsh environments. It's also important to check whether the supplier uses advanced technology to improve the production processes and provide high-quality products at a lower price.

Experience

Experience plays an important role in the manufacturing industry, as it helps manufacturers make better use of their resources and provide better service to customers. It would help if you always chose suppliers or manufacturers with rich experience in this field, who can offer you professional advice on which product best suits your specific requirements. The experienced supplier or manufacturer will solve any problems you may encounter during the production process and help you find effective solutions quickly.

Reputation

A good reputation is a powerful factor in influencing people's decisions when choosing a supplier or manufacturer for their business.

14. Why choose Suzhou Kiande Electric Co., Ltd.'s robot welding machine?

Suzhou Kiande Electric Co., Ltd. is a leading manufacturer of robot welding machines with very advanced R&D and production experience. The intelligent robotic welding machine produced has been exported to Singapore, Japan, Russia, the United States, India, and other countries and regions, Leading the development of the local warehousing industry.

To this day, although we have achieved good results, we have never been satisfied with this, and have always been committed to R&D and innovation, and can make great progress every year. Our intelligent warehousing system is of reliable quality, stable operation, high degree of automation. It has a very high operating efficiency and accuracy rate, which can bring much convenience to the development of the enterprise.

The most important thing is that we can provide very low prices to ensure quality so that more companies can benefit from this. We can also provide a complete service if you need it; welcome to contact us, we will customize a robot welding machine for you, and we look forward to cooperating with you!

15.Robot Welding Machine FAQ

It is believed that our company is the best 2022 Robot Welding Machine Suppliers, which provides customers with excellent quality products. We know you need more than just basic information about our products, such as the price and specification. That’s why here, we’ve prepared frequently asked questions about our products for you, a kind of solution for your questions about our devices.