High Quality Stable Production Capacity Automatic Inspection Machine Specifications :

| Price | Contact us |

| Brand Name | KIANDE |

| Model Number | KD-JCX/NC-E/H-6(4.5) |

| Place of Origin | China |

| Min.Order Quantity | 1 |

| Payment Terms | T/T,L/C,D/P |

| Supply Ability | 100 |

| Delivery Detail | 20days--35days |

| Packaging Details | Wooden case or wooden pellets depended on clients' require |

| Height of Busbar | 100mm~650mm |

| Length of Busbar | 1200mm~6000mm(4500mm) |

| Busbar Type Suited | Straight Type |

| Position Type | Unilateral / Middle |

| Working Efficiency | 2 Min/Piece( Testing time is adjustable.) |

| Nos Of Servo | 2 Axis( Z Axis/X Axis) |

| Vision System | Phase error Judgement( Optional) |

| Printing System | Bar Code Printing/ Report Printing( Optional) |

| High Voltage Withstanding | 0~5000V AC |

| Insulation Testing | 1~1000V |

| Grounding Testing | 0~25A |

| Total Power of Equipment | 3kW |

| Size of Equipment | L12000mm*W1200mm*H1900mm |

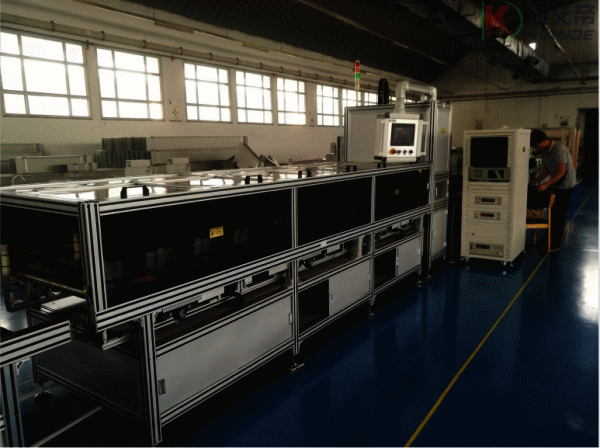

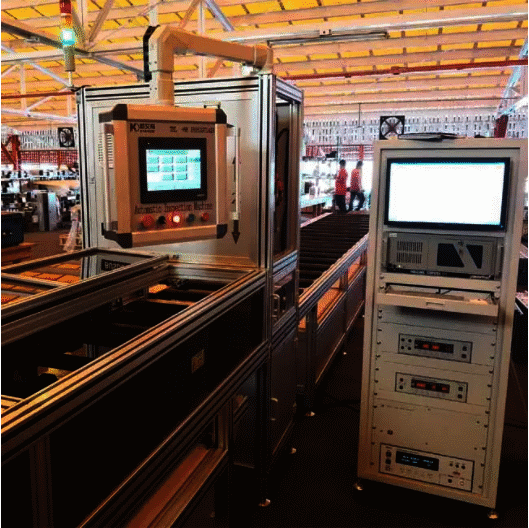

High Quality Stable Production Capacity Automatic Inspection Machine Detail Introduction :

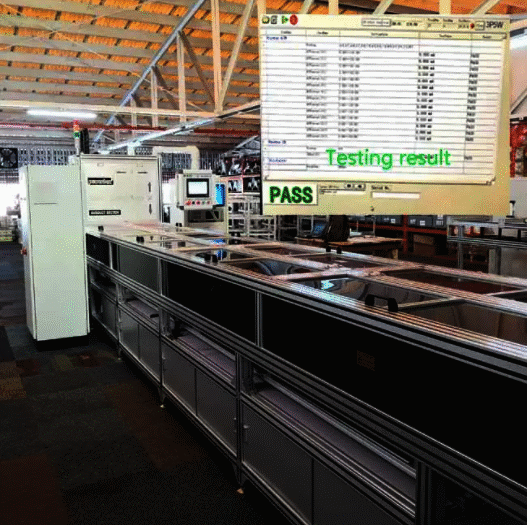

Automatic inspection machine is composed of three parts, feeding position station, inspection station and discharge station. When the busbar enters the fixed position, the control system will select the right testing fixture according to bar code or previous assembly station to start testings of high voltage withstanding, insulation resistance and grounding, make judgement whether it’s qualified and generate testing report. This report can be saved, printed on site and stored remotely etc. It can be set according to customer’s requirements. It is one of the accessories of the busbar machine.

Automatic inspection machine is mainly used for batch inspecting the straight busbar, elbow type should be tested on manual inspection machine.

automatic inspection machine manufacturers & Larger view of the busway machine

Related Products

Related Articles